Brittany from Nashville Tennessee asks,

I have read a lot about Walk On spa covers. I know most covers are not designed to hold much, if any, weight. What is the difference that allows a Walk On cover to support so much weight?

Best!

Hi Brittany,

Lets see if we can explain for you. We will use the example of cardboard. As you know, cardboard is made from all paper, but can have tremendous strength. Cardboard is made by laminating a top and bottom sheet to the “core” of wavy paper inside. The top and bottom sheets, by themselves, have little strength. The inner core of the wavy paper, by itself, has little strength. Combined into cardboard however, the unit operates as a whole and provides great strength for the weight required.

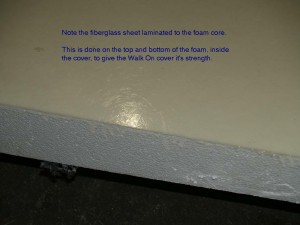

Walk On spa covers are built using much the same principles. A Walk On cover is typically made by adding a top and bottom sheet of fiberglass to the regular foam core used in a non Walk On spa cover.

This picture shows a typical Walk On cover core, showing one side of the laminated assembly.

Walk On covers can be ordered in all of the varying thicknesses, to get the insulation you may need for your environment.

The down side to Walk On covers is the extra weight. Walk On covers will weigh around 90 pounds and can be difficult to remove. If you have a cover lifter device, you must check with the manufacturer to insure it will lift that much weight. If you are shopping for a cover lifter, be sure to ask the same question.

Finally, from the outside, you cannot tell if a cover is a Walk On or not, as the fiberglass is obviously an internal component. How it will look is one component you won’t have to worry about.

Happy Tubbing!

Ethel Elliott