It has been 6 years since I last purchased my spa cover. I am curious what has changed since then in the manufacturing of spa covers. What are the standard features or components in hard, foam core hottub covers?

Bill Baker

Denver, CO

Hi Bill,

Sounds like your cover served you well, especially at your altitude in Denver!

To being to answer your question, let me first list each of the components that make up a typical lid for a hot tub.

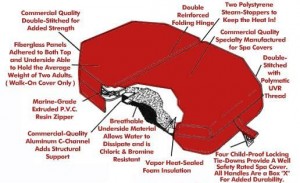

- Foam core

- Vapor barrier

- Vinyl exterior skin

- Skirt/flap

- Four tie down straps with locking clips

Every cover made with a foam core, or hard cover, has at its center a sheet of foam. Typically these are made from expanded polystyrene or EPS. The EPS “beads”, or raw material, are poured into a mold, typically in eight foot by four foot sizes and of varying thicknesses, taper or slope and foam densities. The EPS can either be virgin, meaning it is the first time the EPS beads have been used, or non-virgin. Non-virgin foam cores are less strong than virgin EPS foam due to how the foam is made. Non-virgin foam is simply recycled foam, put into the mold with adhesive and formed into a block. Virgin EPS is shot with steam that causes the EPS beads to expand into the shape of the mold.

Foam density is simply determined by the amount of EPS beads poured into the mold. For example, a 1.0 pound density has exactly half the raw material of EPS beads in exactly the same size mold as a 2.0 pound density foam core. As you would imagine, a block of foam that has twice the foam in the same space will be more dense and therefore stronger.

The vapor barrier is critical to the life expectancy of your top. If not damaged in some way, every cover will eventually fail from water logging. This happens eventually because the chemicals, over time, decay the vapor barrier. Once it fails, the continuous water vapor will begin to soak into the foam and water log the cover. Every cover will have a vapor barrier standard, but be sure to find out the specifics about it. The Pros always recommend upgrading to the best vapor barrier you can.

The vapor barrier wrapped foam cores are held inside the exterior vinyl skin. There are different materials used for this, so you will have to ask. Some use marine grade vinyl, which is designed to handle UV well. Some manufacturers have their own brand of material. The skin is, simply stated, two giant pillow cases, attached to each other with a hinge.

The exterior skin will have a skirt or flap hanging down outside the hot tub. This flap is there to help keep debris from blowing into the tub and to keep the weather and UV from damaging the acrylic lip of the tub. Typically, a skirt up to six inches is offered for no additional charge.

Hard covers come with four tie down straps typically. These are important to help the cover seal to the top acrylic lip of the spa, to maximize the cover’s heat retention. They also help to keep the cover from blowing off in windy conditions.

This should help you understand all the standard features and components. From here, there are a myriad of option and customizations that can be used to make a cover suitable to any use and environment.

Happy Tubbing!

Ethel Elliott